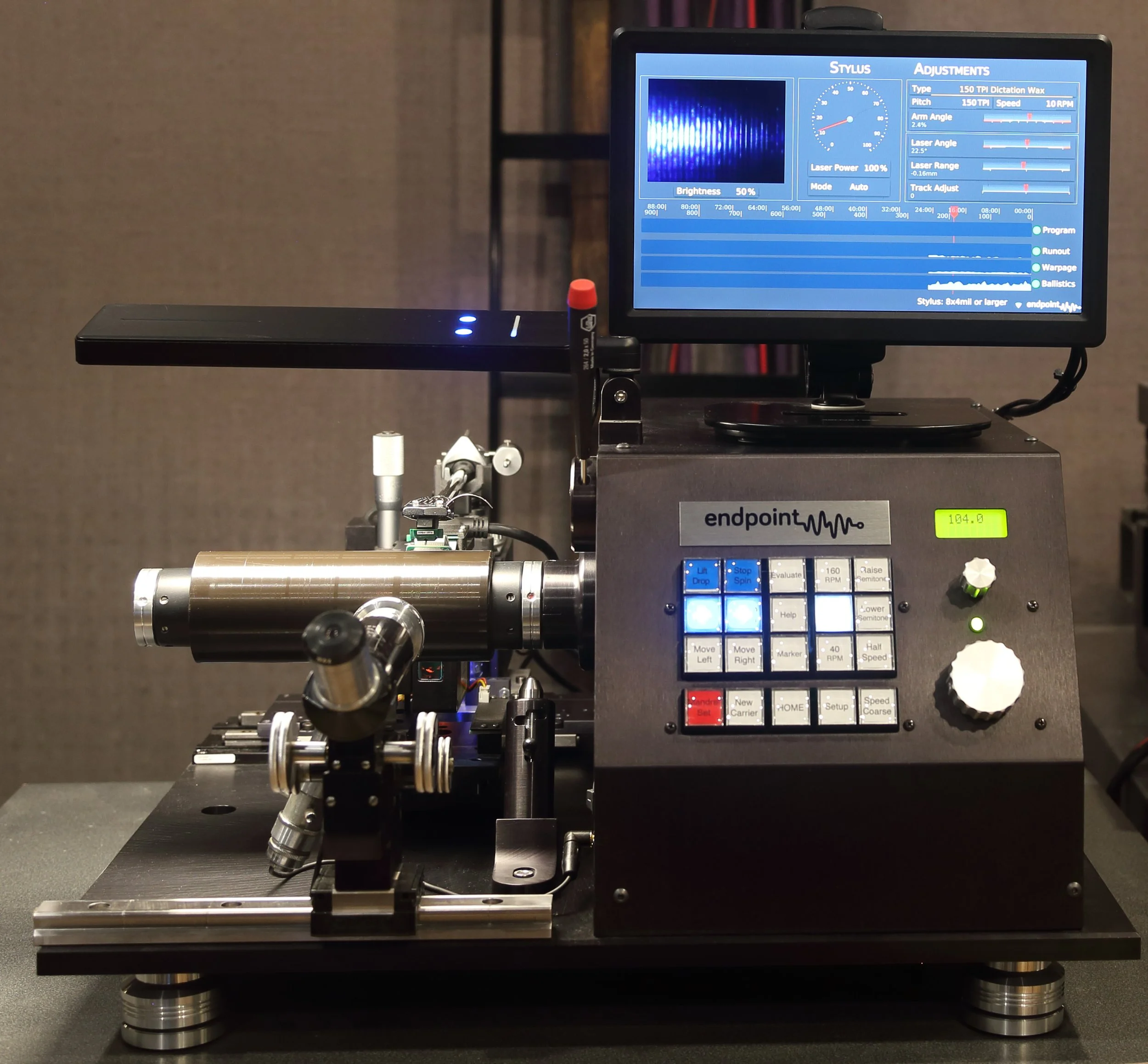

Features

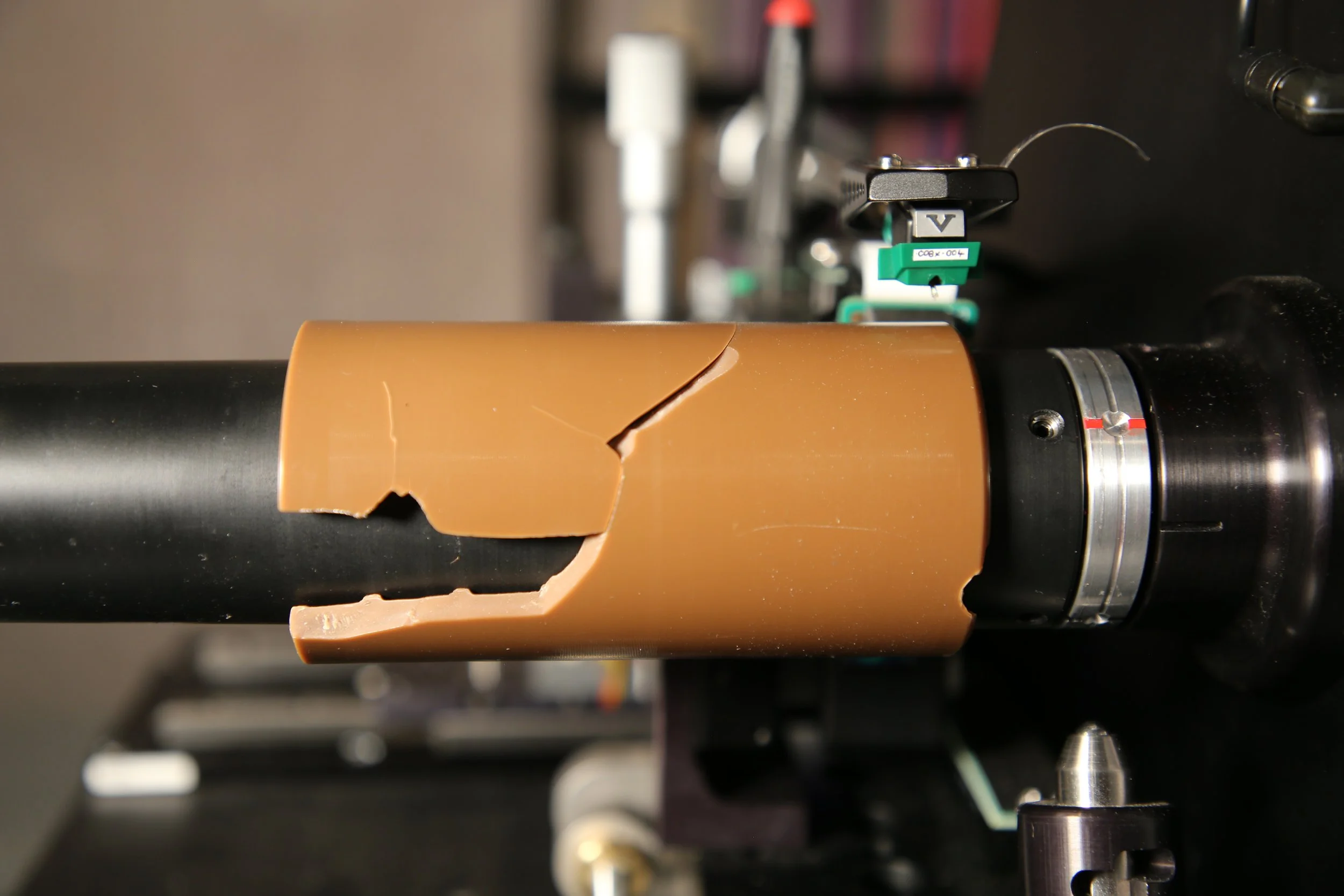

1.Laser-assisted adjustable mandrel and optical playback of broken cylinders

2.Cylinder concentricity adjustable to .001mm resolution

3.De-wow reference tone for eliminating additional wow

4.High throughput safety mandrel

5.Easy mandrel flipping for reverse playback of difficult grooves

6.Simple threaded spindle drive nose for adding custom mandrels

7.Technics-type low wow/flutter brushless DC servo-motor spindle drive

8.Timestep vari-speed spindle control with semitone adjustment

9.Push-button tonearm lift-drop 10. Linear slide with adjustable location points

11.Adjustable vertical tracking angle

12.Low-temperature LED work light with dimmer

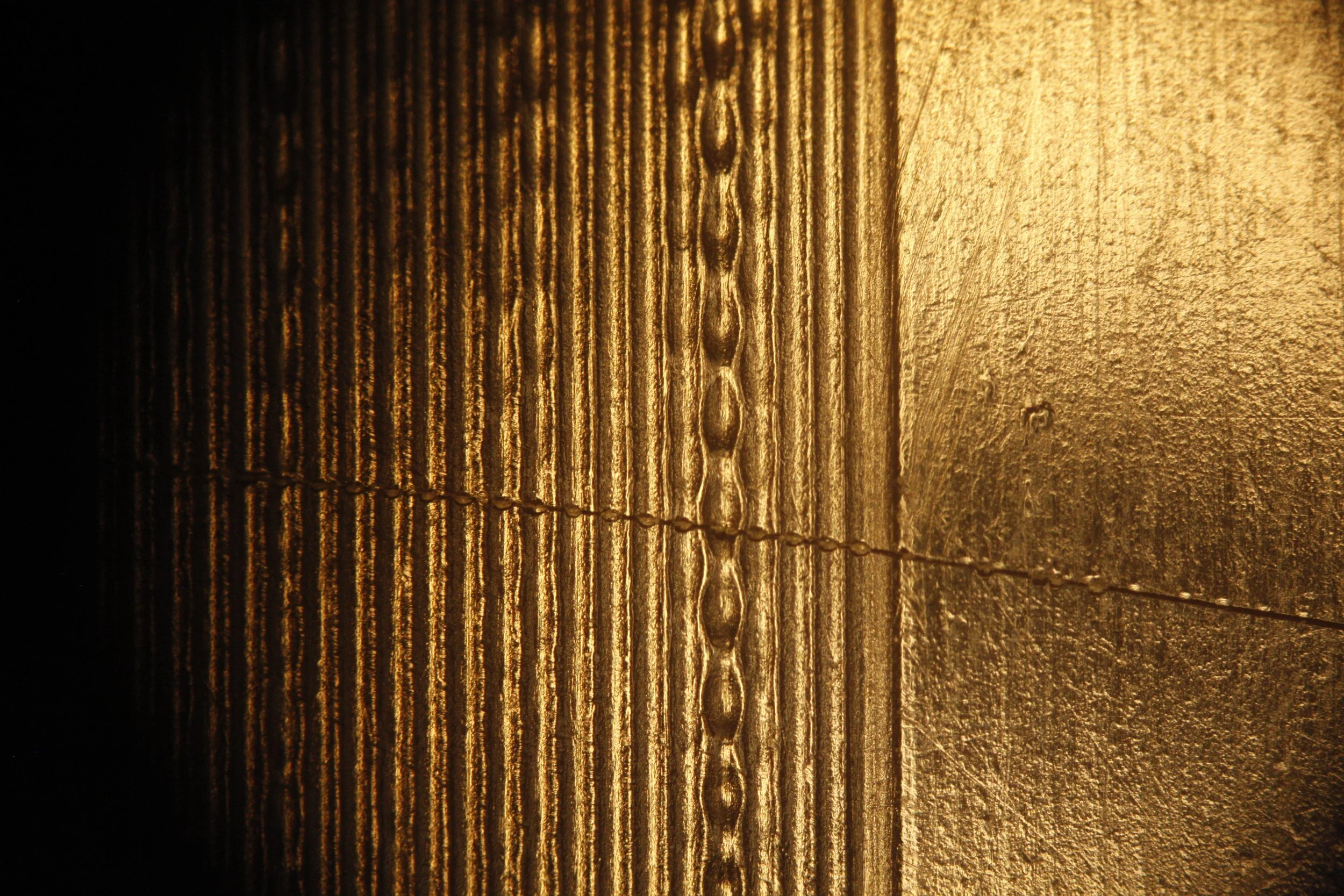

13.Groove Inspection microscope

14.Dictabelt playback features

15.Custom dewow and diagnostic software.

Laser playback of “unplayable” broken cylinder

Video of Endpoint user interface demonstrating laser-assisted centering of out-of-round cylinder

Video of the mechanical features included in the simplest Endpoint cylinder machine version

Dictabelt Playback

A sophisticated spring-loaded expanding mandrel allows for careful tensioning and smoothing of creases. There is ultra low rumble and wow/flutter at the slowest Dictabelt speeds, with laser centering functioning at any speed. In addition, the operator can quickly adjust playback speed.Concert Cylinder Playback

Provides quick switching for concert sized cylinders.Groove Microscope

A unique, long working distance allows microscope to remain usable at a safe distance for cylinder loading and unloading. Features a dark-field incident lighting for excellent groove detail. In addition, there is an optional mount and stand for using same microscope for disc inspection.Camera image through groove microscope show showing scratch across cylinder